- Features & Benefits

-

1.High flow rate! (Immersion / external pressure Types)

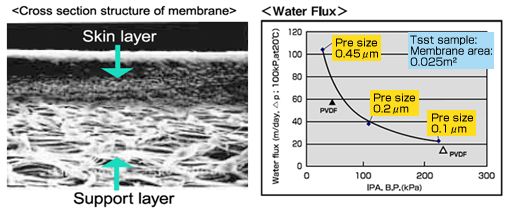

With a high porosity(percentage of void) between 75 and 85% ,resistance during penetration can be reduced, demonstrating a high permeability.

In addition, a double-layer PTFE (Polytetrafluoroethylene) structure consisting of a skin layer (filtration) and support layer offers superior resistance to fouling.

Cross section structure of membrane.

2.Comparison of flow rate (pure water)

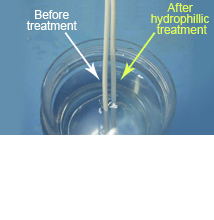

Hydrophilic treatment allows easy transportation and installation (Immersion / External pressure type)

As PTFE (Polytetrafluoroethylene) hollow fiber is subjected tohydrophilic treatment by means of hydrophilic macromolecule fixation, this product can be transported in dry condition. Moreover, hydrophilic property will be kept throughout dry storage after use : therefore there is no problem if you let water run through this this product when it is reused.

3.In comparison with other organic membranes, it is higher in strength, contributing to prolonged operation.

<comparision of hollow fiber strength (nominal pore size: 0.45)>

Tenisile strength (N/fiber) |

Membrane thickness (mm) |

Membrane external diameter (mm) |

Membrane internal diameter (mm) |

|

|---|---|---|---|---|

PTFE membrane (Poreflon™) |

63 |

0.25 |

1.3 |

0.8 |

Other organic membrane |

10 |

0.25 |

1.3 |

0.8 |

4.Membranes can be cleaned with various chemicals and exhibit high flow recovery.

PTFE' s superior resistance to chemicals allows cleaning with high-concentration alkali and other chemicals.

<change after immersion in caustic soda, which is effective in washing off oil and silica>

(Immersion conditions: NaOH 4% ×10 days)

Tensile strength (N/fiber) |

Adhesive strength (N/fiber) |

Remarks |

|||

|---|---|---|---|---|---|

Before soaking |

After soaking |

Before soaking |

After soaking |

||

PTFE membrane (Poreflon™) |

63 |

62 |

> 60 |

> 60 |

Hydrophilic property is kept |

Measurement procedure

Tensile strength (hollow fiber): Measure breaking strength of a sample 100mm in length using a tensile tester.

Adhesive strength (sealed area): Fix the sealed area and pull the hollow fiber upward for measurement Using a tensile tester.

- Line-up and Application

|

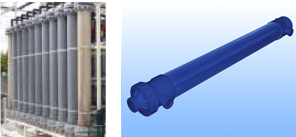

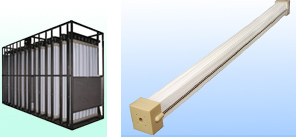

1.External Dead-End style(OPMW) Recommended application ①Industrial waste waster treatment ②Treatment of Waste water including non-aqueous oil ③Water purification system(Water supply) |

|

2.Submerge type(SPMW) Recommended application ①Membrane Bioreactor(MBR) ②Treatment of Waste water of high suspended solution ③Water purification system combined with powder activated carbon and manganese catalyst for the raw water including high soluble manganese and high TOC |

|

3.Internal cross-flow type Recommended application ①Removal of particles from high concentration suspended sulution Removal of bacteria from Fermentation solution ②Treatment of Waste water including High concentration non-aqueous oil Reclaim of used cleaning chemicals |

Caution

- ※Poreflon™ Module and related technical information can be restricted items of Export Trade Control Order. When exporting, if they are restricted items, please have necessary formalities of Export Declaration as your responsibility

- ※Please contact as follows because the quality can change on a part of chemicals.

- ※ When burning PTFE (Polytetrafluoroethylene), acid gas will be produced. Please do not burn it at any cases. The data in this catalogue is a typical value.

The data in this catalogue is a typical value, and general characteristics are described about features and benefits, thus it is not guarantees safety for each type of use. To make sure the safety, you absolutely need to evaluate the conformity yourself. Upon use, we do not have obligation to incidental and indirect accident. Please understand this. The contents of this website is based on materials, information and data available now, thus they can be revised by new knowledge.

Please contact us for details.

- Functional Fluororesin,Sales Dept (Osaka)

- 81(6)6220-4321